Food Processing: Battling the Dark for Clarity and Control

Walk into any food processing facility, and you’ll see workers moving fast-sorting, inspecting, packaging. But what happens when outdated, energy-draining fixtures cast shadows over their work?

Cold storage areas, processing lines, and sanitation zones need precision lighting-not scattered, uneven illumination that leaves critical details in the dark.

- Contamination Risks Rise: A minor imperfection in a product goes unnoticed under poor lighting, leading to costly recalls or compromised safety.

- Accidents Multiply: Dimly lit pathways and slippery floors create an unseen danger zone for employees rushing to meet production demands.

- Inefficiency Becomes the Norm: When maintenance teams constantly swap out failing bulbs or deal with unexpected shutdowns, productivity takes a hit.

SafeGlo™: Built for the Toughest Environments

Designed to thrive in the cold, moisture-heavy conditions of food processing, SafeGlo™ transforms poorly lit spaces into brilliantly illuminated, safety-first zones.

With its lightweight, easy-to-install design, it seamlessly integrates into your facility—reducing labor costs, maintenance hassles, and compliance worries.

Industrial Beverage Production: Shielding Against Heat, Humidity, and Hazards

If you run a brewery, distillery, or large-scale beverage production facility, you know one thing for certain: heat, humidity, and flammable vapors are the enemies of traditional lighting.

When lighting fails in these extreme conditions, the risks are severe:

- Production Disruptions: The last thing you need is flickering lights slowing down bottling lines or causing critical readouts to be missed.

- Explosion Hazards: Vapors from fermentation and distillation processes hang in the air, one small spark from the wrong lighting source can be catastrophic.

- Constant Maintenance Costs: Cheap fixtures degrade fast, forcing your team into an endless cycle of replacements and repairs.

SafeGlo™: Lighting That Works as Hard as You Do

SafeGlo™ isn’t just another industrial light, it’s built for the punishing environments of beverage production. Its moisture-resistant, high-temperature-safe design means your lighting won’t fail when you need it most.

And with faster, hassle-free installation, your team spends less time fixing problems and more time keeping production moving.

Brewery & Distillery Floors: Where Safety & Visibility Matter Most

From fermentation tanks to bottling lines, consistent, explosion-proof lighting is non-negotiable. SafeGlo™’s advanced Ex m Encapsulation technology prevents ignition sources, keeping your facility and employees protected, even in areas prone to flammable vapors and liquids.

The SafeGlo™ Advantage: More Than Just Light—It’s Peace of Mind

Why SafeGlo Is Your Solution

SafeGlo™ Series: the first of its kind, engineered to tackle the hazards of poor illumination head-on, SafeGlo™ provides pinpoint lighting for long, complex spaces, ensuring safety and efficiency.

No more makeshift solutions. No more compromises. SafeGlo™ brings clarity, control, and confidence to your workspace.

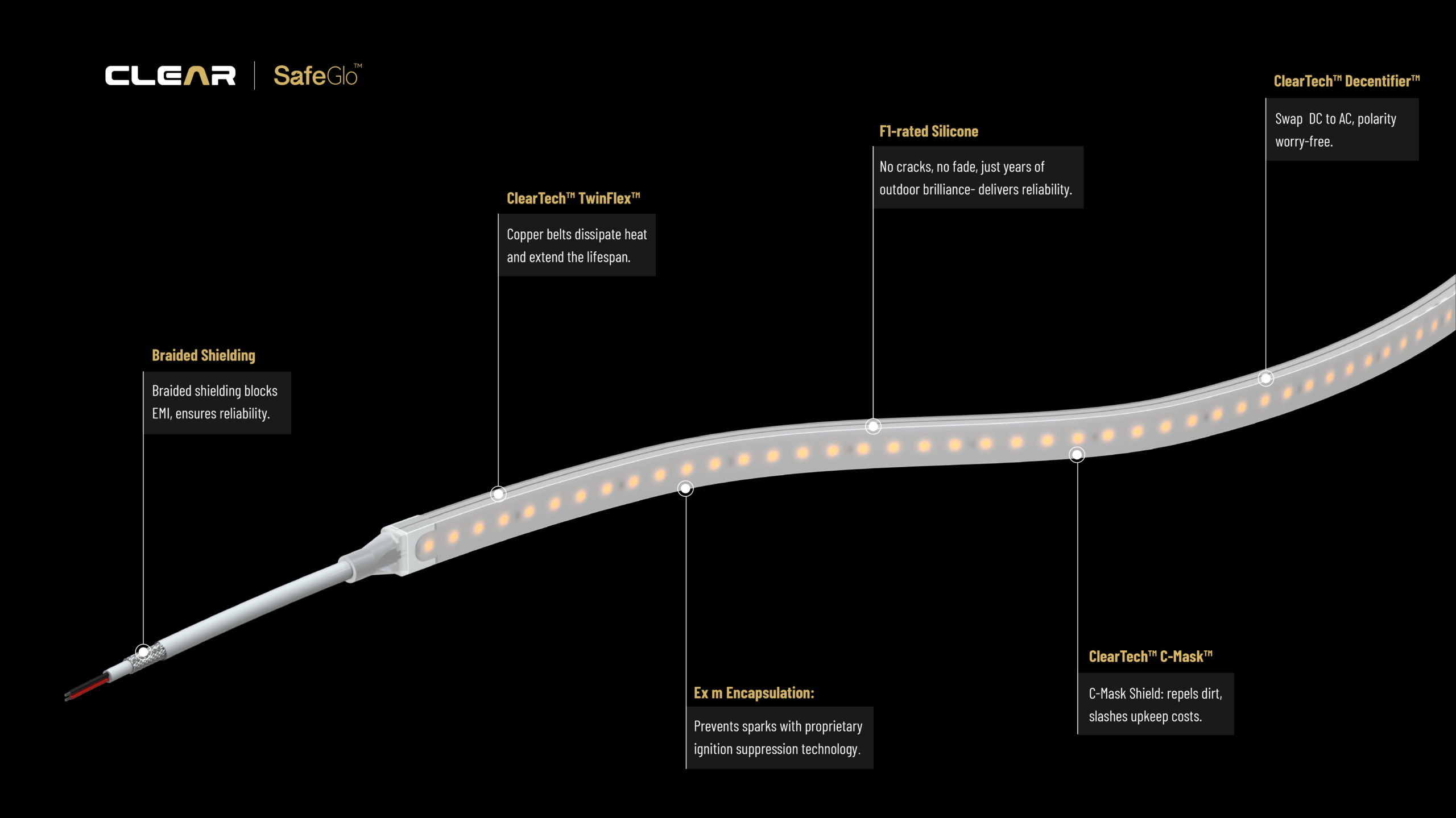

SafeGlo™ Product Features

Transform Your Workspace with SafeGlo™ Series

Your operation isn’t average. Your lighting shouldn’t be either.

You already know that inadequate lighting puts your business at risk. The real question is, how much longer can you afford to put up with it?

See the difference. Feel the impact. Experience SafeGlo™.

Take the first step toward a safer, more productive facility.