Compliance Isn’t Enough. Your Lighting Should Actually Solve Problems.

When was the last time your lighting solution did more than just meet regulations?

Traditional explosion-proof fixtures are built for checkboxes, not real-world mining conditions.

- Overbuilt, rigid housings fail in tight spaces and extreme heat.

- Corrosive dust infiltrates fixtures, leading to premature failures.

- High-voltage systems struggle in volatile, methane-rich tunnels.

Where SafeGlo™

Transforms Mining Operations

Open-Cut & Surface Mines

Static, high-voltage fixtures struggle in vast, exposed mining zones.

Heat buildup, dust ingress, and frequent repositioning demands lead to premature failures and safety hazards.

(F1 Rated) withstands monsoon rains & blasting debris.

Adapts seamlessly to conveyors & excavation equipment, preventing dark zones.

Below ignition thresholds—even at 80°C ambient.

Underground Tunnels & Temporary Worksites

Portable lighting often sparks ignition risks and can’t handle vibration in methane-heavy zones.

Eliminates sparking risks in methane-rich tunnels.

Withstands rock abrasion, extending life span of the strip light.

Install quickly in confined spaces, slashing downtime by 40%.

Processing Plants & High-Humidity Zones

Humidity, corrosive fluids, and poor visibility slow down inspection workflows and destroy conventional lighting.

Repels hydraulic fluids and grime, reducing cleaning labor.

Prevents polarity errors in rushed shift-change installations.

extend lifespan, cutting replacements by 60%.

Mining-Centric solution

- ClearTech™ Decentifier: No polarity errors during rushed installations, critical in shift-change environments.

- Silicone F1 Rating: Withstands blasting debris & extreme weather.

- Ex m Encapsulation: Prevents sparks in an environment where methane levels surge unexpectedly.

- C-Mask™: Slashes weekly cleaning labor in coal processing zones.

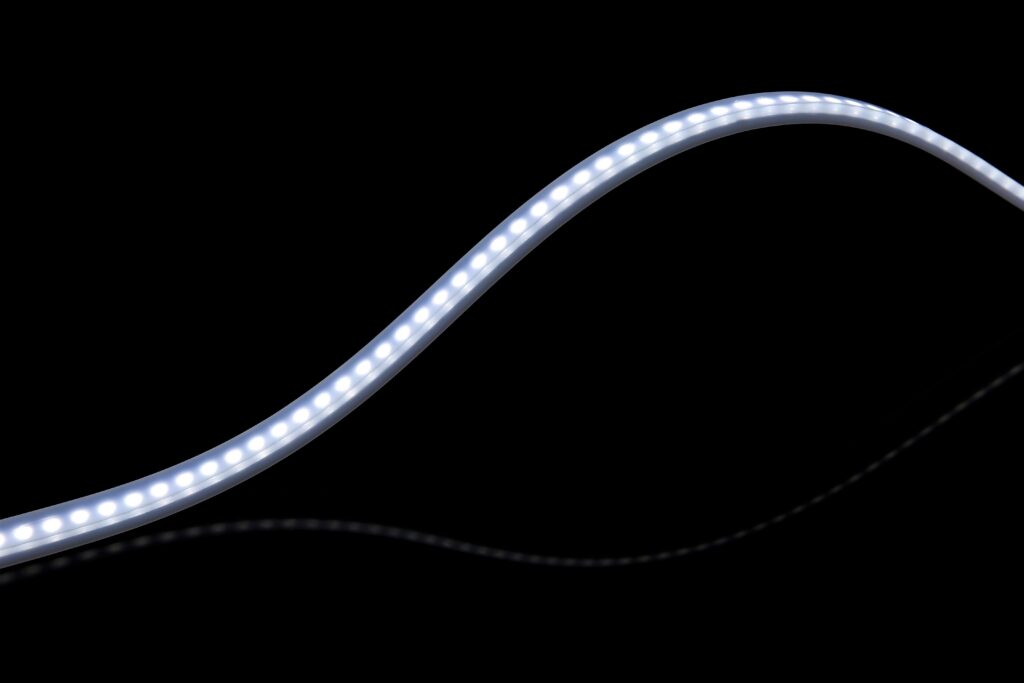

- TwinFlex™: Bends around ore crushers without PCB breakage, ensuring safer operator visibility.

Stop Fighting Your Lighting. Start Trusting It.

SafeGlo™ isn’t just about compliance, it’s about outlasting, outperforming, and outdelivering every other explosion-proof light in the market.

No more patchwork solutions. No more compromises. Just mining purpose-built lighting that delivers.